What is DTF Printing?

Understanding the Basics of DTF

Direct to Film (DTF) printing is a modern method for transferring digital designs onto various fabrics, offering high-quality prints with vibrant colors and excellent durability. Unlike traditional screen printing or Direct to Garment (DTG) printing, DTF involves printing a design onto a film, which is then heat-pressed onto the fabric.

Background of DTF Printing Development

DTF printing technology emerged as a response to the limitations of other fabric printing techniques. DTG printing, for instance, is ideal for cotton but less effective on polyester or blended fabrics. Screen printing, while versatile, requires more setup time and is less suited for complex, multicolor designs. DTF provides a flexible, efficient, and reliable alternative, offering compatibility with a wide range of materials.

Advantages of DTF Printing

Superior Print Quality

DTF printing produces crisp, detailed images with accurate color reproduction. The prints have a soft, smooth finish and retain color integrity even after repeated washing, thanks to the high-quality inks used in the process.

Compatible with Various Fabrics

DTF printing can be applied to diverse materials, including cotton, polyester, and blends. This versatility makes DTF ideal for customized apparel across different industries, from sportswear to casual fashion.

Efficient Production Process

DTF printing is fast and efficient, supporting high-volume orders without compromising on quality. This makes it a preferred choice for B2B customers who need quick turnarounds for large batches, ensuring consistent, reliable results.

High Durability

The DTF printing process produces durable designs that withstand frequent washing and wear. The adhesive used in DTF printing ensures that the print bonds well with the fabric, reducing the chances of peeling or fading.

DTF Printing Workflow

Design Preparation

Before starting the DTF process, it’s crucial to prepare a high-resolution design file. Adjustments to resolution and color settings should be made to optimize for vibrant, accurate prints. Vector files are often recommended for the best output quality.

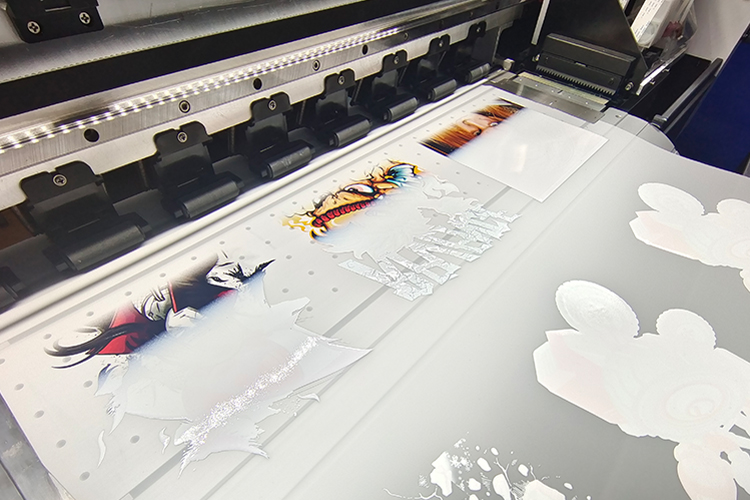

Printing and Transfer Process

The DTF workflow involves a few key steps:

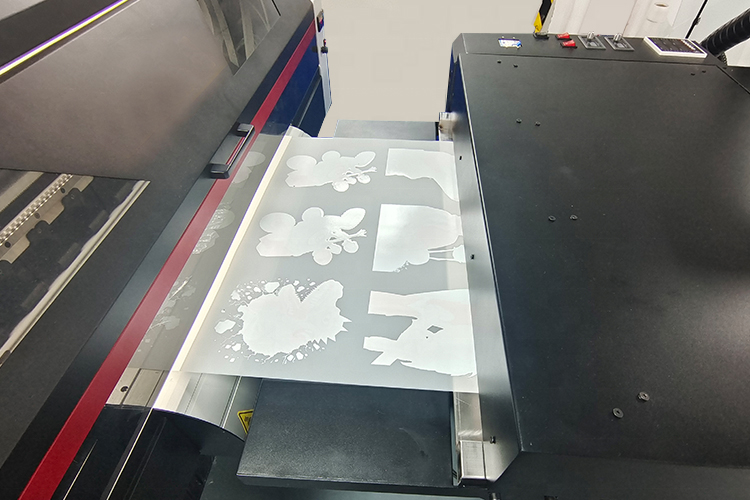

- Printing: The design is printed onto a special PET film using DTF-compatible inks.

- Powder Application: An adhesive powder is applied to the printed design, helping it bond with the fabric during transfer.

- Curing: The powder-coated film is cured to activate the adhesive, setting the stage for a seamless transfer.

- Heat Pressing: The film is pressed onto the fabric under controlled temperature and pressure settings, ensuring a long-lasting transfer.

Post-Transfer Treatment

After transferring, the fabric undergoes a cooling phase, allowing the design to set completely. This step helps ensure that the print remains intact, preserving its quality and durability.

Equipment and Materials for DTF Printing

Printers Suitable for DTF

DTF printers are specially designed for high-resolution output and compatibility with various inks. Reliable DTF printers should offer consistent performance, accurate color reproduction, and adaptability for different fabrics.

Heat Transfer Film

The choice of transfer film is critical in DTF printing. High-quality PET films ensure precise transfers, minimizing any loss of detail or color. Look for heat transfer films that offer durability, flexibility, and smooth adherence to fabric.

Ink Types for DTF

DTF-compatible inks, including water-based and eco-friendly options, provide excellent color vibrancy and longevity. These inks are designed to withstand washing and daily wear, ensuring that the print remains vibrant over time.

Equipment and Materials for DTF Printing

Printers Suitable for DTF

DTF printers are specially designed for high-resolution output and compatibility with various inks. Reliable DTF printers should offer consistent performance, accurate color reproduction, and adaptability for different fabrics.

Heat Transfer Film

The choice of transfer film is critical in DTF printing. High-quality PET films ensure precise transfers, minimizing any loss of detail or color. Look for heat transfer films that offer durability, flexibility, and smooth adherence to fabric.

Ink Types for DTF

DTF-compatible inks, including water-based and eco-friendly options, provide excellent color vibrancy and longevity. These inks are designed to withstand washing and daily wear, ensuring that the print remains vibrant over time.

Important Considerations in DTF Printing

Design Tips

To get the best results, avoid overly complex designs that may be difficult to transfer. Pay close attention to resolution and color settings, and test smaller runs to ensure compatibility with specific fabric types.

Equipment Maintenance

Regular cleaning and maintenance of DTF printers and heat presses extend their lifespan and prevent issues such as ink clogging. Proper maintenance helps ensure that the equipment operates smoothly for high-quality output.

Care and Washing Guidelines

DTF-printed garments should be washed with care to maintain the design’s integrity. Use mild detergents, avoid high heat in washing and drying, and consider washing the items inside out.

Future Trends in DTF Printing

Technological Advancements

As technology progresses, DTF printing equipment is expected to become even more efficient and environmentally friendly. Innovations in ink formulations and transfer films are likely to improve both the print quality and durability.

Market Demand

The demand for DTF printing is growing due to the versatility and quality it offers. Industries like fashion, sportswear, and promotional goods see significant potential in DTF for producing vibrant, long-lasting designs.

Conclusion and Recommendations

DTF printing combines flexibility, efficiency, and quality, making it an excellent choice for custom apparel and branded merchandise. Its compatibility with different fabrics, ability to produce intricate designs, and high durability are valuable assets for B2B clients looking to create impactful, lasting apparel products. With the ongoing advancements in DTF technology, this method is set to become even more prevalent in the industry, offering new opportunities for customization and scalability in garment printing.